Description

Product Description

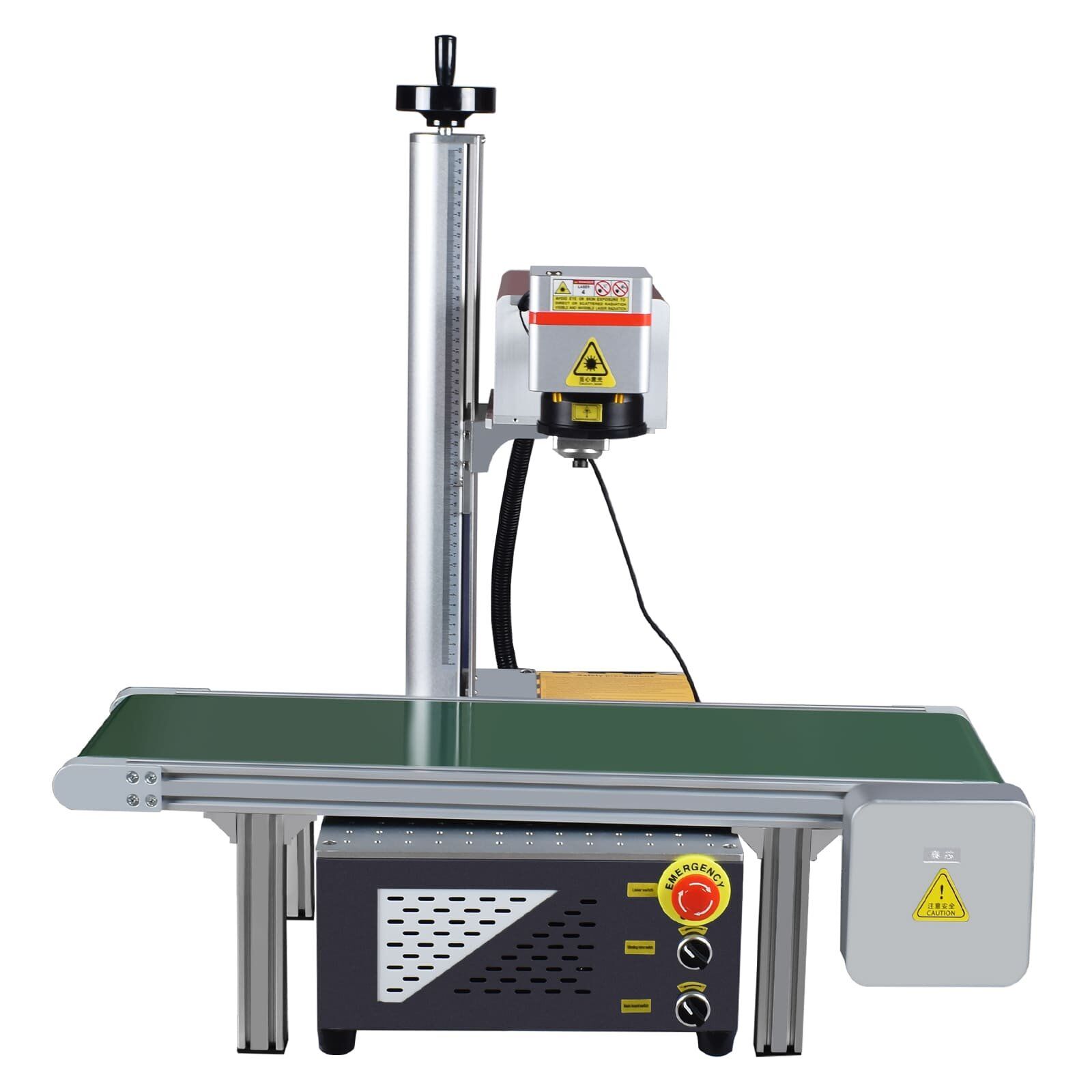

The UV Laser Marking Machine with CCD Vision System & Conveyor is a high-precision automatic laser marking solution designed for continuous industrial production lines. It integrates a 355 nm UV laser source, a CCD visual positioning system, and a conveyor belt module to achieve accurate, repeatable marking on moving or randomly positioned workpieces.

The built-in CCD camera captures real-time images of the workpieces and automatically identifies reference features, allowing the system to correct position and angle deviations without manual alignment. Even when multiple identical parts are placed arbitrarily on the conveyor, each item can be marked at the same predefined position with high consistency.

Using UV laser “cold marking” technology, the machine delivers extremely fine marking quality with minimal thermal impact, making it ideal for applications where surface integrity, precision, and contrast are critical. The system supports multiple marking modes, including standard marking, camera-assisted visual marking, and conveyor-based continuous marking, providing flexible operation for different production requirements.

This machine is widely used in electronics, plastics, glass, PCB, medical products, and other industries that require high-precision, automated laser marking.

Key Features

-

355 nm UV laser for cold marking with minimal heat-affected zone

-

CCD vision system for automatic positioning and deviation correction

-

Conveyor belt for continuous, high-efficiency batch processing

-

Accurate marking on small, irregular, or randomly placed parts

-

Supports text, graphics, codes, and precise visual alignment

-

Stable industrial design suitable for long-time operation

Typical Applications

-

Electronic components and micro parts

-

PCB and FPC marking

-

Plastic and glass products

-

Medical devices and consumables

-

Automated production and traceability lines

Technical Specifications

| Category | Specification |

|---|---|

| Laser Type | UV Laser |

| Laser Wavelength | 355 nm |

| Laser Power Options | 5W / 10W |

| Laser Classification | Class 4 |

| Required Optical Density | OD > 6 @ 355 nm |

| Marking Method | Non-contact UV laser marking (cold processing) |

| Vision System | CCD visual positioning system |

| Positioning Mode | Feature recognition with automatic position & angle correction |

| Marking Modes | Standard marking / Visual marking / Conveyor continuous marking |

| Canvas Function | Built-in camera canvas for visual alignment and layout |

| Conveyor Type | Integrated desktop automation conveyor belt |

| Conveyor Operation | Continuous batch processing |

| Recommended Conveyor Width | Approx. 200 mm working zone |

| Z-Axis Adjustment | Manual height adjustment with scale ruler |

| Control Software | Mantismark |

| Connection Methods | Ethernet (LAN) / WiFi |

| Offline Operation | Supported (files downloadable to control panel) |

| Control Functions | Start / Pause / Stop / File Download |

| Supported Content | Text, vectors, graphics, vision templates, arrays |

| Cooling System | Air-cooled or Water-cooled (depending on configuration) |

| Cooling Water Temperature | 25 ± 1 °C (water-cooled version) |

| Cooling Medium | Purified water |

| Rated Voltage | 220–240 V AC |

| Rated Frequency | 50 / 60 Hz |

| Safety Features | Emergency stop, laser warning system |

| Compliance Standards | IEC 60825-1, EN ISO 11553-1 |

| Typical Applications | Electronics, plastics, glass, PCB, medical products |

More Product Images – Scotle UV Laser Marking Machine with CCD

Reviews

There are no reviews yet.